About Junhao

Junhao Machinery has been deeply rooted in the machinery equipment industry for many years. With a professional and efficient core team and a comprehensive service system covering pre-sales consultation, in-sales debugging, and post-sales operation and maintenance, it has steadily developed into a professional equipment supplier with strong technical capabilities and extensive market influence in the industry. Particularly in the niche field of intelligent welding robots, Junhao has established a unique core competitiveness, becoming a significant force in driving the intelligent upgrading of the industry.

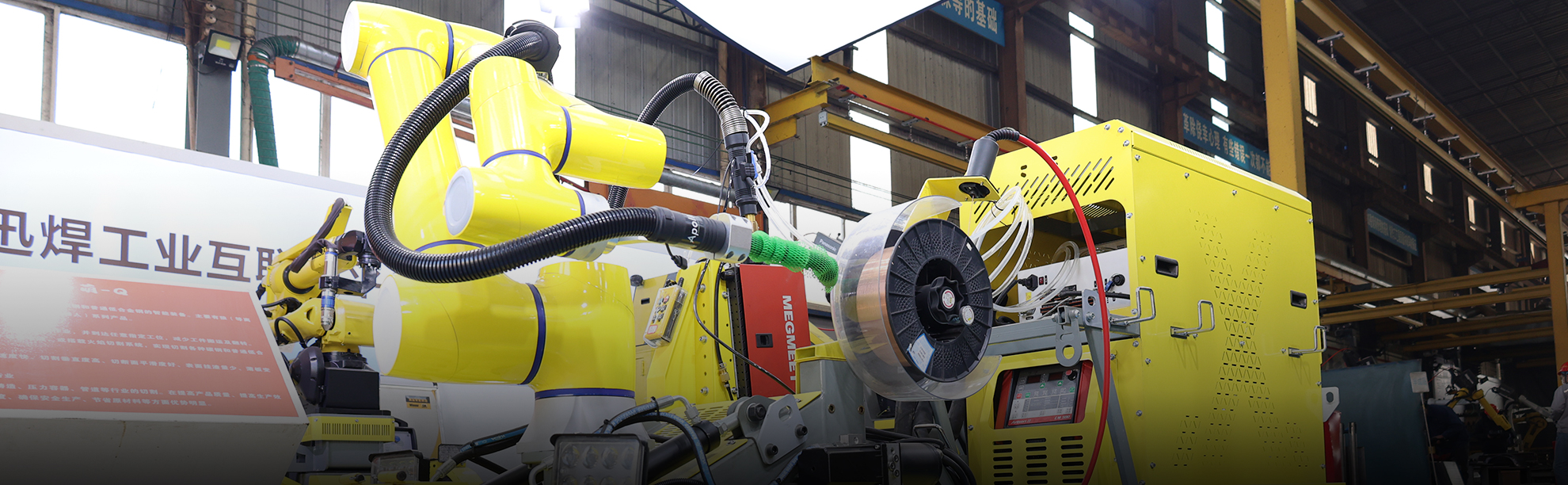

In terms of scientific research and technological strength, the company attaches great importance to the independent research and development of core technologies. It has set up a professional R&D team led by multiple doctors and senior engineers, built a provincial-level enterprise technology center and an industry-university-research cooperation platform, and maintained a high level of R&D investment all year round (R&D investment accounts for more than 8% of annual revenue). Focusing on the technical pain points in the field of intelligent welding, the team has achieved multiple breakthroughs in core technologies such as autonomous walking control, precise positioning welding, and industrial internet collaboration. It has accumulated more than 50 invention patents, utility model patents, and software copyrights. The core technologies are widely applied to core products such as full-scenario mobile welding robots and 7-axis fixed welding robots, ensuring that the technical performance of the products is always at the leading level in the industry.

In terms of production strength, the company has built a modern intelligent production base with an area of over 20,000 square meters. Equipped with multiple automated production lines and precision testing equipment, it realizes full-process standardized production from core component processing, whole machine assembly to finished product testing. At the same time, the company has established a strict quality control system and passed the ISO9001 quality management system certification. It implements strict multi-link testing from raw material procurement to product delivery to ensure the reliability and stability of each piece of equipment. The annual production capacity can reach more than 1,000 units, which can efficiently respond to the diverse order needs of the market.

Adhering to the core tenet of "market-oriented, quality as life, technology as motivation, and credibility as the foundation", the company deeply empowers multiple key industries such as construction machinery, new energy, steel structures, wind power, shipping, and bridges with its core technologies and high-quality products. By providing full-scenario intelligent welding solutions, it effectively solves the pain points in various industries such as non-standard large workpiece welding, high-risk environment operations, and unstable welding quality. It helps cooperative enterprises significantly reduce labor costs, improve production efficiency, optimize product quality, and ensure operational safety, promotes the upgrading of production models and the optimization of industrial structures in related industries, and injects strong momentum into the high-quality development of the manufacturing industry.

While creating commercial value, Junhao Machinery actively fulfills its social responsibilities. On the one hand, by replacing high-intensity, high-risk, and high-repetition manual welding operations with intelligent welding robots, it greatly reduces the incidence of safety accidents in the welding industry, improves the working environment of front-line workers, and fulfills the industry mission of "liberating human resources". On the other hand, the company's technological innovation and industrial empowerment drive the coordinated development of the upstream and downstream industrial chains, create a large number of jobs related to R&D, production, and services, and help local industrial upgrading and economic development. In addition, the company actively participates in the formulation of industry standards, promotes the application of intelligent welding technology, drives the standardized and intelligent development of the industry, and at the same time practices the concept of green production, reduces equipment energy consumption through technological optimization, and helps the green transformation of the manufacturing industry.

In the future, the company will continue to focus on key areas such as construction machinery, new energy, and steel structures, take full-scenario mobile welding robots and 7-axis fixed welding robots as the core product matrix, continuously deepen technological innovation and service upgrading, and continuously help cooperative enterprises achieve the production upgrading goals of "cost reduction, efficiency improvement, quality enhancement, and safety assurance". It will further fulfill the industry mission of "liberating human resources and creating value together", strive to become a world-leading intelligent welding solution service provider, and contribute more to promoting the intelligent transformation of the manufacturing industry and boosting the high-quality development of social economy.