Core Technologies Behind Junhao's Intelligent Welding Robot

Views: 1 Time: 2026-01-01 14:00:30

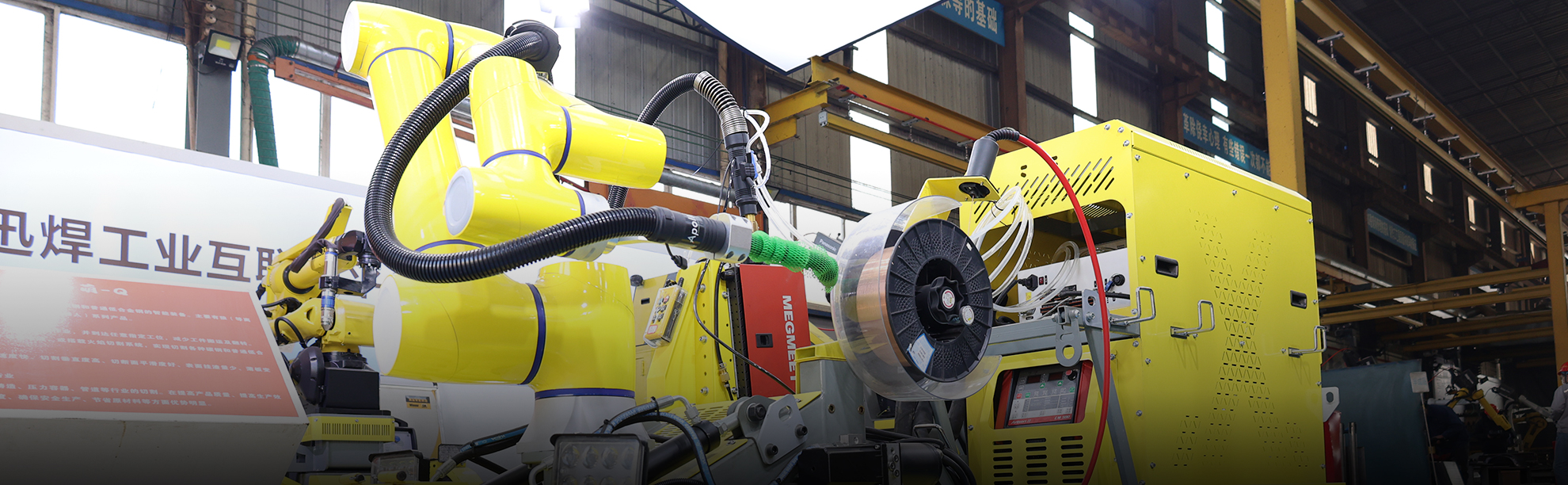

Precision and intelligence are the core competitiveness of Junhao's welding robot in the market, which is supported by the synergy of multiple core technologies. In terms of positioning accuracy, the robot is equipped with an advanced hydraulic positioning system and a bionic leveling system, with a repeat positioning accuracy of up to ±0.03mm. Even in complex working environments, it can maintain stable operation, ensuring uniform welding quality of each weld seam, and fundamentally solving the problem of uneven quality in manual welding. In terms of welding process, the robot adopts the industry-leading Gas Metal Arc Welding (GMAW) process, combined with a flexible configuration that can adapt to welding wires with diameters ranging from ф0.8mm to ф1.6mm. It can easily handle various welding positions such as horizontal welding, flat welding, vertical welding, and overhead welding, adapting to the welding needs of workpieces of different materials and thicknesses. At the intelligent control level, the robot is equipped with the Fourier Industrial Internet Platform, featuring the core advantage of one-time programming for repeated operations. Programming data can be stored unlimitedly in the cloud, and a large number of welding processes can be updated and shared in real time, greatly reducing the workload of repeated programming and simplifying the overall workflow. Meanwhile, supported by real-time monitoring and cloud-based data storage functions, operators can remotely grasp the welding process and quality status, which not only improves the safety and convenience of operation but also realizes the full-process traceability of the welding process, enabling the robot to perfectly adapt to the complex needs of various non-standard welding tasks.